EXAKT in the Automotive Industry

Predicting Hoist failure – EXAKT at a North American car plant

Summary:

In 2006 under the guidance of the University of Toronto’s Department of Mechanical and Industrial Engineering, a project was completed to determine whether vibration analysis could form a definitive predictive model for hoist chain failure. The chain hoists at the auto plant form a critical and integral part of the production line. With an extremely high cost of failure, management responded with a regime of early preventive replacements – thus avoiding failure, but at the same time, reducing the useful life of the hoist and increasing replacement costs. Using EXAKT, the project developed a predictive model which would alert management to impending failure in time to take preventive action but without wasting valuable hoist life.

EXAKT is an advanced failure prediction software package, developed by the Condition-Based Maintenance Laboratory, led by Professor Andrew Jardine at the University of Toronto. By analyzing wear on the hoist chains and correlating it with impending failure, EXAKT provided a statistical decision tool to accurately predict whether the hoist could continue to run until the next shutdown. The key questions were “can the use of EXAKT as a CBM (condition based maintenance) tool improve the chain hoist replacement decision? Extend chain life? Predict failure? And reduce costs?”. The answers were “yes”, “yes”, “yes” and “probably”.

Plant management now has a software tool that will extend hoist life while providing the added comfort of predicting the probability of failure before the next planned outage, and putting a confidence level on the prediction.

Three important lessons were learned:

1. as part of the regular preventive maintenance program, 12 measuring points were regularly monitored, collecting data on five different variables. Many of these data points turned out to not be predictors of failure.

2. because of the extremely high cost of failure, no actual failures were permitted during the assessment period. Consequently the cost modelling was based on estimates rather than actual experience. This threw into question the accuracy of the cost savings measurement – but did not invalidate the strong belief that significant cost savings were achievable.

3. Based on the analysis, EXAKT can now be used to assess the failure risk for other hoists in the plant – in fact a key recommendation was that immediate action be taken to prevent an expensive failure of one of the other hoists that was not due for preventive maintenance.

BACKGROUND AND OBJECTIVES:

The hoist is used to transfer car bodies from one stage of production to the next. Several similar chain hoists are used in the assembly process; the failure of any one of them will halt production, and require multiple shifts at overtime rates to repair the units. As a result, rather than risk expensive failure, plant management instituted a policy of deliberate premature replacement – preferring to waste useful life rather than risk the high failure cost. The purpose of the project was to evaluate whether EXAKT could recommend an alternative methodology for predicting the remaining useful life of the chain hoists, extending their operating duration and reducing the overall maintenance costs – all without seriously increasing the risk of failure. This element of failure prediction within the current production run was the task demanded of EXAKT. The thrid risk element – that of ascribing confidnece levels to the probability prediction – is also a function of EXAKT.

Management had clearly recognized the high costs of failure:

1. the cost of a breakdown repair (damage to the equipment, expedited parts, emergency and overtime crew costs) extending over a repair period of several shifts

2. the value of lost production caused by the breakdown or slowdown

3. the loss of reputation as a consistent and reliable supplier, and the consequent loss of market share at a time when strong competition is ever-present.

The EXAKT methodology was required to take these into consideration.

METHODOLOGY:

The starting point was a detailed review of the current data to evaluate its consistency, accuracy and adequacy for predictive model building. An 8-year history was examined, and (as noted) one unusual element was the absence of actual failures due to plant managements aggressive preventive replacement policy. The monthly schedule of preventive maintenance (including lubrication) plus a bi-annual re-build policy was augmented by careful vibration measurements each six weeks. This was all planned and tracked using Maximo.

The next step – in the absence of actual failure – was to decide what would constitute a “failure” for the purposes of the project. Based on internal procedures and advice from the manufacturer, it was established that linkage wear of 1.5% to 1.8% was enough to prompt a preventive replacement. Failure was postulated and agreed therefore at 2% wear rates. This was factored into the selected best-fit model.

The company’s existing predictive maintenance program measured shaft speed, three vibration variables, the magnitude of the vibration and the amplitude of the peak vibration for each of the twelve measuring points. The next step in the analysis process was to correlate these readings with operating data such as hoist loads, operating hours and numbers of vehicles lifted. These operating data were analyzed to create an estimate of working age – a key factor in EXAKT failure predictions. Resulting from this analysis, it was shown that the number of operating hours would act as a statistically satisfactory proxy for working age.

From this data, a statistical model was developed that would correlate the condition monitoring data with actual failure or potential failure events.

A series of EXAKT Weibull Proportional Hazards models was developed to determine which of the many combinations of variables would provide the best predictive capability. The best-fit model used three variables – the magnitude and peak vibration readings from the outboard sprocket, plus a derived factor for the inboard sprocket calculating the sub-synchronous energy variable. This latter variable had not historically been measured; alternative models excluding this variable did not have a sufficiently high predictive capability and thus were rejected. Plant management subsequently introduced a consistent methodology for regular measuring of this variable to use as the basis for their on-going predictive program. Other data points which were shown to have no predictive capability could then be discarded. As each new set of inspection data is received, the model automatically recalibrates and returns a revised optimal interpretation of the CBM data.

A key part of the predictive capability was the development of a transition probability model. This shows the probability of a variable in a current range of values deteriorating to the next higher level of failure frequency. One significant result of this analysis for example, showed that an outboard sprocket with a vibration magnitude of more than 0.78 inches per second had a 30% probability of failure before the next scheduled outage. This proved to be critical information in reformulating the company’s preventive maintenance program.

Because no failures had previously occurred, the use of the failure cost ratios could not be measured with any degree of accuracy. Based on estimates, a ratio of 12:1 was used – indicating that the cost of a failure was (based on very conservative numbers) 12 times that of a preventive action. Because of this, the cost report – which shows the cost savings gained from the optimum balance of preventive maintenance and run to failure – could be used as an indicator only. However this restriction did not invalidate EXAKT’s value as an important predictor of failure.

Further analysis of the cost factors showed that the sensitivity of the model’s results to variances in the ratio of preventive costs to failure costs was in fact very low. Consequently any reasonable variations in the actual failure cost would support the same conclusions. Thus plant management decided to use the model to predict the expected date of failure rather than as a method of cost reduction – even though significant cost reduction would be an expected by-product.

RESULTS:

Applying the EXAKT prediction model to other similar hoists in the plant answers the questions – Should the company keep the unit in operation until the next scheduled outage? Or should they take preventive action prior to the shutdown?

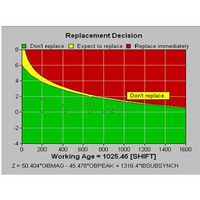

The EXAKT decision graph below shows the current status of the equipment and the recent trend of the measured variables. Each data point tracks the weighted sum of the selected significant CBM (condition based maintenance) measurements against the working age for a specific hoist. As long as the current value is in the “Green Zone” ( the lower segment in the graph), then the equipment can be expected to last until the next scheduled inspection. Readings in the “Danger Zone” (the upper segment) indicate the company will lose money by continuing to operate and incurring a breakdown

- in simple terms, the equipment is overdue for breakdown.

Additionally an “expected remaining life estimate” is reported – important for scheduling maintenance on the unit. Maintenance managers now have persuasive data to halt production, undertake emergency preventive maintenance and remove the consequences of a full breakdown.

The “Caution Zone” (between Green and Danger) indicates that the best decision will be to perform maintenance within the next inspection interval. The formula at the foot of the screen calculates the weighted sum of significant monitored variables as determined by EXAKT. The conclusions (“Don’t Replace” respectively) are shown in the text boxes on the graph.

CONCLUSIONS:

1. EXAKT failure prediction and decisions models were successfully developed and tested for the hoist’s failure modes at the 95% confidence level.

2. This prompts plant management to use EXAKT as a trigger for preventive replacements of similar hoists.

3. Much of the currently measured condition data were found to be of little or no value in predicting failure, plus one key variable was missing.

4. Because no actual failures had occurred, and thus no failure costs were measured, the EXAKT cost model could not confidently be used to predict the cost reductions resulting from the new failure prediction dates; however plant management was satisfied that that actual cost savings would be significant.

Ben Stevens – July 2007