Frequently asked questions

The following questions appeared recently

(July 2004) on the PlantMaint list service in response to the "Elusive P-F Curve" article that was

published at Reliabilityweb.com. http://www.reliabilityweb.com/art04/p-f_curve.htm

|

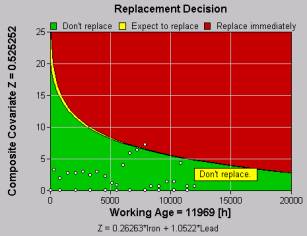

Question 1. Referring to your graph on the right, does EXAKT ignore “high points” that occur at a lower age and therefore do not cross over the green-to-red threshold? For example let’s say you have a sudden high vibration reading but it is still in the green region. Isn’t it dangerously negligent to ignore such a signal? |

|

Answer

Although EXAKT does not recommend a renewal for a

“high point” that is still in the green region, the

“abnormal” vibration reading may indeed be caused by problems (either not

directly related to the risk of failure or to the failure mode being addressed

by the model). For example, the item being monitored may be a complex item, one

that is subject to more than one failure mode. If that is the case, the

reliability engineer, may elect to build, and arm the EXAKT agent with, a second

decision model. The agent will sequentially apply the second model, one that

targets a (different) failure mode (whose risk of failure may be more

dominantly reflected by vibration[1]).

Alternatively, the reliability engineer may

manually add warning limits to the model to suggest, for example, a more

intrusive inspection of the unit, or a calibration check on the instrumentation

used in collecting the vibration data. In EXAKT, this feature sets up

descriptive warning limits that will be superimposed upon the optimal decision

graph. The warning limits act as additional guidance for maintenance personnel

to act[2].

A final point to note is that, the CBM Lab

designed EXAKT to extend current methods in on-condition maintenance.

Thus, if human interpretation of monitored data reveals a new failure mode, not

addressed by the current EXAKT model, the human expert may elect to update or

add this ‘new’ experience to the intelligent decision agent’s ‘knowledge base’.[3]

The “cost comparison” function in EXAKT provides a means for monitoring the

improving effectiveness (towards the attainment of an objective) of a

model as time proceeds and new

experience accrues.

The shape of the boundary curve in the

decision graph depends on the value of the shape parameter[4]

in the PHM (proportional hazards model). If the shape parameter equals 1, the

boundary curve will be a horizontal line. The graph shown above represents the

situation when the shape parameter is much greater than 1. In this instance,

the working age dominates the other significant risk factors, such as vibration

level, that you refer to in your question.

To explain this more clearly, we can treat

the age itself as a risk factor (the actual variable is log(age)) in the model.

Now we have two risk factors: the age and the vibration level. If

we fit the model[5] with shape

parameter fixed to one[6],

the model will be the same as one fitted with only a single risk factor, the

vibration level. (Of course, in the retained model, shape parameter is not

fixed to 1). The advantage of using a model that treats age as a risk factor is

that we can see the effect of age (compared with other factors) on the risk of

failure.

Using the actual EXAKT model, however,

we observe (by noting the shape of the boundary curve) that the shape

parameter is, in fact, greater than 1. That says that the risk of failure is

dominated by the age factor. It does not say that the vibration level is

not important. Instead, it says that the vibration level is not as

important as the age factor. Hence, in this instance, where a high vibration

level does appear at an early age, the decision graph in EXAKT advises that there is no need to renew[7]

the unit.

Question 2. SAE JA1011 states: “Any mathematical and statistical formulae that are used in the application of the [RCM] process (especially those used to compute the intervals of any tasks) shall be logically robust, and shall be available to and approved by the owner or user of the asset.” How does EXAKT meet this requirement?

Answer

As a general response, EXAKT’s algorithms’

statistical, mathematical, and logical robustness pass muster in the open

literature. Professional and academic

peer reviewed journals have published many papers that describe the CBM Lab’s

theoretical and practical development work in EXAKT. Here are just a few of those

references:

-

-

Jardine, A.K.S.,

Anderson, P. M. and Mann, D. S. (1987), “Application of the Weibull

proportional hazard model to aircraft and marine engine failure data”,

Quality & Reliability Engineering International, 5, 77-82.

- - Jardine, A.K.S., Banjevic, D., Wiseman, M., Buck S. and Joseph T. (2001). “Optimizing a mine haul truck wheel motor’s condition monitoring program: use of proportional hazards modeling”, Journal of Quality in Maintenance Engineering, Vol. 7, No. 4, pp. 286-301.

- - Makis, V. and Jardine, A.K.S. (1992). “Optimal replacement in the proportional hazards model”, INFOR, Vol. 30, pp.172-183.

-

- Vlok, P.J., Coetzee, J.L., Banjevic, D., Jardine, A.K.S. and Makis,

V. (2002), "Optimal Component Replacement Decisions using Vibration

Monitoring and the PHM", Journal of the Operational Research

Society, 53, pp. 193-202.

- - Daming Lin, Murray Wiseman, Dragan Banjevic, and A.K.S. Jardine (2004) "An approach to signal processing and condition-based maintenance for gearboxes subject to tooth failure" Mechanical Systems and Signal Processing, Volume 18, Issue 5 , September , Pages 993-1007

As a more specific answer we may discuss

some of the basic algorithms used in EXAKT. The first step in the development

of an EXAKT optimal decision model requires that we build a “proportional

hazard model”. The process consists of applying each variable monitored by a

CBM task to the EXAKT model creation process. In the procedure we test whether

a monitored variable does indeed correlate with past failures (functional or

potential). If it does, then that variable becomes a candidate for our

proportional hazard model. EXAKT uses an algorithm based on the Maximum

Likelihood Estimation method to fit the model to the available data. It then

uses extensive statistical testing to verify how good the resulting model

is.The figure below shows the window in EXAKT where these tests are initiated.

Once the

PHM is built and tested, we proceed to build the decision model. Once that is

done, we invoke additional statistical methods for investigating and testing

the decision model. A snapshot showing these features is shown below.

Finally,

once the reliability engineer is satisfied with the decision model, he (she)

exports it onto the network where it assumes the role of an “intelligent agent”

or “watchdog agent” that silently monitors new data as it arrives into one or

more databases[8]. The agent

generates its optimal interpretations as records in a database table. These

records may be accessed by the CMMS, ERP, or any other programs or humans

requiring the results of the CBM decision analysis.

Although

we have had several successful case studies with our industrial partners, the

final validation of the EXAKT methodology will be its wide acceptance and

implementation in industry. We are confident that this will come soon.

Question 3. Why at time zero does Z appear to be infinity?

Answer

The boundary curve corresponds to the

optimal hazard level h*. In other words, all the points on the curve have the

same hazard level h*. You can imagine doing a hazard rate contour plot here.

The boundary curve is the contour with hazard level h*. In this example

decision graph, the smaller the age, the bigger the value of Z should be to get

the same hazard level h*. This is why you observe a wider range of Z under the

boundary curve at earlier age. At age zero, any real value of Z will lead to a

zero hazard level. So, to have the same hazard level h* at age zero, Z must be

infinity. According to the way the decision graph is meant to be read, this

does not mean that you are going to have infinite Z in reality. The boundary

curve just divides the whole space for (age, Z) into two parts: the area under

the curve and the area above the curve. If the point (age0, Z0) corresponding

to your readings lies in the area above (under) the curve, it means that the

current hazard level is above (below) the optimal hazard level h* and the

decision would be to replace (not to replace) the unit. For more detail on the

decision graph, please see “Optimal replacement policy and the structure of

software for condition-based maintenance”, Journal of Quality in Maintenance,

V. 3, No. 2, pp109-119.